Manufacturing: Utilisation of production capacity by large enterprises, May 2025 released by Stats SA on Thursday indicated that utilisation of production capacity by large manufacturers was 77.7% in May 2025 compared with 77.6% in May 2024, an increase of 0.1 of a percentage point. Economists have described it as positive news.

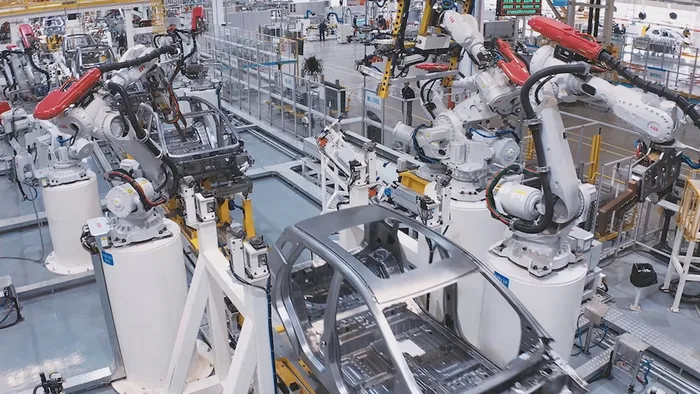

Image: supplied

South Africa's manufacturing landscape revealed a modest improvement in production capacity utilisation for large enterprises, as new data from Stats SA indicates an increase to 77.7% in May 2025 from 77.6% in May 2024.

Economists are interpreting this 0.1 percentage point rise as a positive indication of resilience within the sector.

According to Stats SA, six out of the ten major manufacturing divisions recorded increases in production capacity utilisation compared with the same month last year.

Notably, the glass and non-metallic mineral products sector led the way with a significant rise of 2.5 percentage points, followed by textiles, clothing, leather, and footwear which saw an improvement of 1.8 percentage points.

Three divisions notably surpassed the critical threshold of 80% capacity utilisation in May 2025.

The food and beverages sector topped the list at 82.6%, signalling strong demand, followed by glass and non-metallic mineral products at 81.0%, and furniture along with other manufacturing at 80.2%.

This data suggests that certain sectors may be gearing up for a robust performance in the coming quarter.

Investec chief economist Annabel Bishop said that capacity utilisation by large manufacturers rose to 77.7% in May, from 76.2% in February this year on the three-month reading, mainly as shortages of raw materials decreased as did downtime.

“This is supportive of the improvement in industrial production noted so far for the second quarter, which rose by 1.4% for the first two months in Q2.25 versus the first two months of Q1.25,” she said.

“The highest rates of utilisation of productive capacity were in the manufacture of processed food and beverages (82.6%), potentially heralding a good quarter for some food agricultural products, glass and non-metallic mineral products (81.0%), furniture and ‘other’ manufacturing (80.2%).”

Bishop said that the largest increases for Q2.25 versus Q1.25 were recorded in the manufacture of coke and petroleum products (13.8%), processed food (7.1%) with reports of improved production coming through; furniture (4.3%) and glass and non-metallic mineral products.

“May saw capacity utilisation for the manufacture of motor vehicles, parts and accessories and other transport equipment fall by -1.0% as the industry was not able to scale back immediately on April’s 25% US tariff on imports of automotives and parts.”

Bishop added that June saw an intensification of tariffs on steel and aluminium products, with the impact still to come on the capacity utilisation readings.

Professor Raymond Parsons, a North-West University Business School economist, said that high-frequency data like utilisation of production capacity by large manufacturers were important for future investment trends in the sector.

“Once the manufacturing industry becomes convinced that there is a sustained improvement in markets and capacity utilisation, they are more willing to plan for investment expansion. However, it is still early days to expect too much response at this stage,” he said.

Parsons added that although the May utilisation trends were pointing in the right direction, they were still marginal and below optimum levels.

“Recent Nedbank data suggests that the private sector’s overall fixed investment level so far this year is still weak. And the uncertainty and impact surrounding the latest US tariffs remain very relevant for future investment decisions in sectors like the SA motor industry.”

Professor Waldo Krugell, an economist at North-West University, said the uptick in the manufacturing: utilisation of production capacity by large enterprises was very small.

“In a way, it does indicate that the economy is ticking along; it’s not growing in manufacturing. As much of the other high-frequency data would indicate, it's not shrinking, but it's not growing at the rate we would want,” he said.

Krugell added the industry will be looking at more data as it waits for the impact of the tariffs imposed by US President Donald Trump hitting the motor industry.

“We hope that this won’t have a major impact on the economy and it can continue ticking along.”

BUSINESS REPORT